Introduction

A chilled beams is an air circulation device with a necessary loop that might be introduced inside a space to give reasonable cooling and warming. It is an air distribution device that utilizes water to move reasonable warmth to and from a room. It is made of convective coils that are put in the roof of a thermal zone to give reasonable cooling and potentially warming.

Chilled beams can be two pipes or four pipes. The two pipe is used when there is only cooling needed and the four pipes is used when there is necessity of both cooling as well as warming. The use of chilled beams was first started in 1986 with the main passive chilled beam being introduced in Stockholm, Sweden.

Types of Chilled Beams

There are two principle types of chilled beams, such as,

- Active chilled beam

- Passive chilled beam

Active Chilled Beams

Active chilled beams are those that have ventilation work provided to them giving a particular measure of essential air to the compressed plenum inside the device to be released through acceptance spouts, blend in with entrained air and ventilate the room. Active beams ought to be used when reasonable warming, cooling and ventilation air are required.

On the off chance that the plan calls for beneficial cooling just or the total ventilation necessities of the building’s design are being met by some different means, passive beams might be utilized. Private and public places of business, study halls, medical services office, meeting offices, different conditions that might have moderate to high reasonable warmth proportions, and building retrofits where space for new mechanical hardware might be restricted are largely acceptable applications for active chilled beams.

Passive Chilled Beams

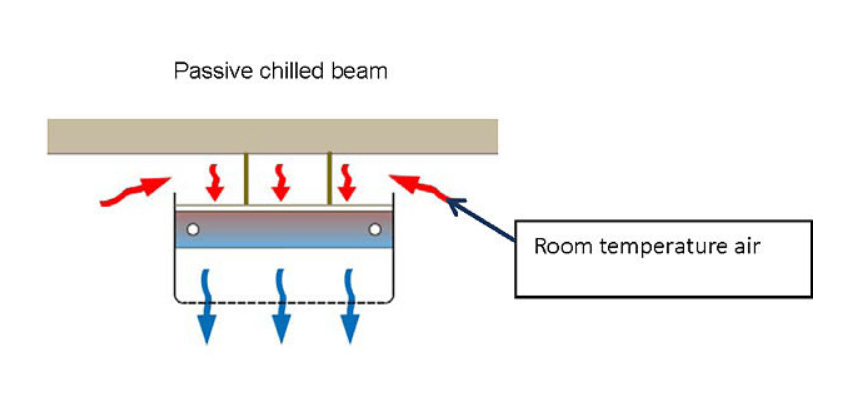

Passive chilled beam is one that isn’t deducted, doesn’t supply essential air and doesn’t use fan controlled hardware for any piece of the air that crosses the curl. They depend on enlistment air being drawn across the loop by the regular gravitational forces and buoyancy of air. Warm air ascending to the roof enters the beam from above as the chilled air that has gone through the loop drops down.

The movement of the cool air dropping make a pressure drop behind it that draws all the more warm air through the curl. Passive chilled beams are a decent answer for give reasonable cooling in labs or different spaces where cycles and individuals produce high warmth loads, particularly those that are delicate to changes in pressure or ventilation and require no extra air flow.

A few applications might have a ventilation rate necessity or sufficiently high idle burden that a conventional HVAC framework would be more suitable for use than active chilled beams, yet could profit with the utilization of passive beams for valuable cooling. Building retrofits where extra cooling is required yet the first ventilation framework will stay set up are likewise acceptable passive beam applications.

Because of the inclination of the warm air to ascend to the roof, delineation in conceivable with all air dissemination devices if the release air temperature is excessively high or release speed is excessively low. With chilled beams, delineation is conceivable if the temperature of the water entering the loop is excessively high. Because of air speed and the blending needed to circulate offered air the involved zone, passive beams ought not be utilized for warming applications.

Multiservice beams are another type of chilled beams. Eventually, they would be considered either active or passive yet a multi-administration beam joins other building capacities into its design, like lightning, sound gadgets, fire sprinklers, movement locators and other different alternatives. To appropriately choose and execute multiservice beam designs, broad coordinated building design is vital. Multiservice beams are appropriate for applications, for example, retrofits where space for a few high innovation frameworks may not be promptly accessible, applications that might profit with off-site assembling of introduced specialized administrations and designs where make stylish inside engineering, even in situations when floor tallness is low.

Designs where chilled beams would likely not be a fitting innovation to use would be natatoriums, saunas, restrooms, storage spaces, kitchens or different regions in which the beams might be presented to high dormant additions, buildings with helpless envelopes or those that might have operable windows with no strategy for control where beams might be quickly presented to outside temperature and humidity and conditions.

Chilled Beams Advantages

Different techniques for design exist, each having their own arrangement of hazard and prize. Chilled beam framework can give a few advantages, including:

- Potential decreases in beginning expenses of gear and development material.

- Space versatility.

- Increase in inhabitant solace past that which is reachable through conventional frameworks.

- Simple activity and support.

- Energy proficiency.

First expense conversations of chilled beam frameworks every now and again include presumptions that the principle expenses of giving chilled beams are higher than those related with giving conventional air conveyance items. That is right, obviously, while considering just the air dispersion gadget itself. Nonetheless, that suspicion doesn’t consider the decrease in sizes and limits of other gear and development material.

Customary frameworks, include blending return air with outside air, accordingly taking care of the complete stock air volume and reasonable limit at the air taking care of unit. Chilled beams frameworks handle return air and reasonable burden inside the space, lessening the all out volume of supply air and moving incomplete burdens from the unit to the space which brings about a huge abatement in the measure of ventilation work required.

Diminishing space needed for the ventilation work can yield critical reserve funds in floor to floor stature space prerequisites, leaving more space for inhabitant, measures and sometimes in any event, lessening expenses of primary parts of diminishing generally building tallness. Dealing with the reasonable burden with the space and recycling entrained air likewise considers critical decrease in size and limit of air overseer segments like warming or cooling loops, supply fans, channels and so on, which often lessens the complete generally speaking size of the air controller.

An increment, in generally speaking solace space adapted with chilled beams is for the most part an after effect of the abatement in commotion, temperature irregularity and draft conditions. Where customary overhead air conveyance frameworks might create sound levels in the scope of NC 35 to 40. Chilled beam frameworks commonly work with sound levels under 20 NC.

Chilled beams are designed to convey air at lower speed than standard overhead frameworks, in this way diminishing the chance of horrendous draft conditions. Furthermore, the design of chilled beams brings about profoundly viable blending of room air and essential air supply which brings about agreeable and predictable room temperatures.

Designing a chilled beam framework as per a versatile system can permit adaptability in design that might deliver ideal indoor environment conditions for the existence of the building, paying little mind to changes of utilization or format inside the space. The flexibility is cultivated by using chilled beams with choices like air quality devices, speed regulators and controls that take into consideration water stream and temperature guideline.

For instance, a speed regulator can be physically acclimated to any of various positions, which change the size of the release opening in this way, expanding or diminishing the toss. The regulator marginally affects limit, sound and pressure. An air quality device is important for a versatile design that enables and users to increment or diminishing natural air cfm to change the chamber pressure to coordinate with the accessible channel pressure at branch.

The customizable device can be physically or electronically moved to open or close the finish of the plenum where essential air can be released into the space without intersection the loop or affecting the productivity of the enlistment spouts in the active part of the beam.

Regardless of weather air is being provided at the base ventilation rate or then again whenever blended air is being provided, a way to deplete air from the space is needed to keep up with proper building pressure. An exhaust valve choice goes about as an extra method of mitigating air from the room. The exhaust valve is coordinated into the chilled beam on either the left or right half of the beam.

In chilled beam applications, the are ordinary two lengths referred to absolute length and active length. The active length shows the length of the loop inside the beam. All out length is for the actual beam including the compressed plenum and design packaging. On the off chance that an exhaust valve alternatives is chosen, the active length of the beam is diminished.

Energy effectiveness in design is a significant justification late expansions in popularity of the utilization of chilled beam systems. The treatment of return air and the reasonable load inside the space that happens with the use of chilled beam technology yields a few energy effectiveness benefits. Eliminating all or part of the reasonable load from the air controller diminishes the energy utilization there, and the potential energy misfortunes experienced while the air is conveyed through the ventilation work to the space.

Isolating reasonable cooling loads from ventilation loads, airflow supply rates might be diminished to supply fulfill lease ventilation prerequisites. Using chilled beams with a steady volume devoted outside air supply (DOAS) unit that conveys required least ventilation rate airflow might diminish the general measure of open air being provided and hence decline the energy yield needed to treat that air.

Because of the way that chilled beams use instigated air from the space and air shouldn’t be gotten back to the unit to be reconditioned, fan energy utilization at the air overseer is diminished.

Notwithstanding, energy reserve funds because of changing air development and limit contemplations, chilled beams offer energy investment funds identified with chiller efficiencies also. Chilled beam systems necessitate that higher temperature chilled water be provided to the beams. In conventional systems, the water used by customary subordinate air dealing with devices, for example, fan coils and terminal units be provided at somewhere in the range of 40 to 45 degree Fahrenheit.

With chilled beam systems chilled water ought to be provided at temperatures no lower than 55 degree. The distinction in water temperature supply prerequisites might create critical expansions in chiller energy productivity. The need to warm cooled air is diminished by the arrangement of higher chilled water supply temperatures and by the blending of the treated essential air supply with the huge volume of entrained air from the room.

Activity and upkeep of chilled beam systems is exceptionally solid, straightforward and undeniably more averse to require support or new parts. In many designs, filtration happens upstream, so substitution channels are not needed for singular beams. Administration costs are negligible. Rare as well as fundamental vacuuming of the coil, which can be gotten to through a hinged front board in many devices, is normally all the upkeep needed for the actual beam.

For more information click here.