Honeycomb in concrete refers to the cavities and voids on the surface of the concrete or inside the concrete. It is caused due to less clear cover or improper vibration and sometimes due to bleeding of concrete.

Here it is discussed about what is honeycomb in concrete, types of honeycomb in concrete, causes of honeycomb in concrete, effect of honeycomb in concrete, how to avoid honeycomb in concrete and honeycomb concrete repair.

What is Honeycomb in Concrete?

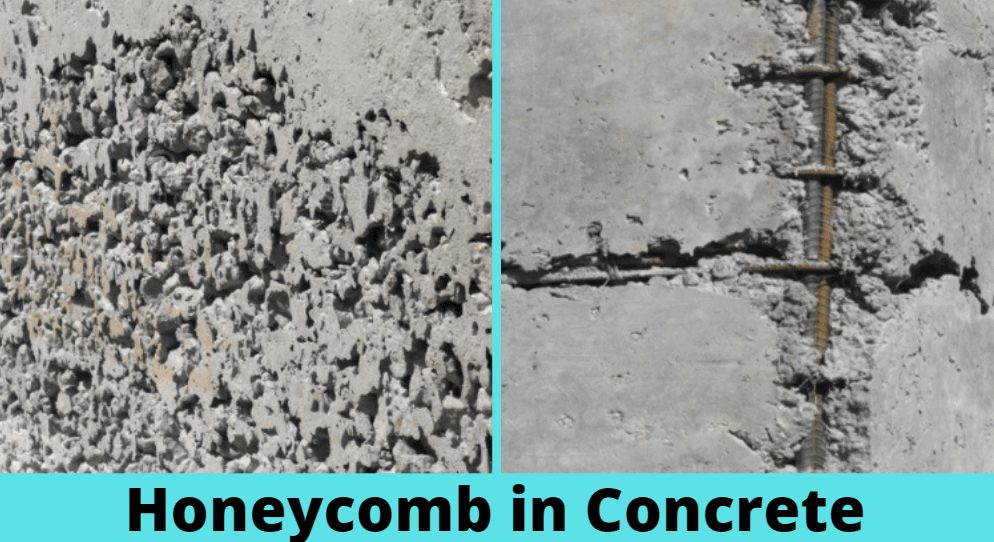

Honeycomb refers to the cavities and voids on the surface of the concrete or inside the concrete. It is named as honeycomb because the pattern of the cavities and voids looks similar to a bee nest.

The surface honeycomb in concrete can be detected as soon as the formwork of the structure is removed, but the honeycombs which are inside the concrete can be detected by advanced techniques such as ultrasonic tests and others.

Honeycomb structure in concrete is a very serious issue in construction. It not only reduces the concrete strength but also makes the reinforcement of the structure vulnerable to water and moisture and as a result corrosion takes place on the bars.

Corrosion is the process which takes place in the reinforcement bars and as a result the bars start loosing its bond with the concrete which makes the structure very dangerous in its life expectancy.

When honeycomb in concrete occurs the coarse aggregates are seen on the surface of the structure with less bonding of mortar due to which it leaves cavities and voids.

Honeycomb commonly occurs in columns and beams, and sometimes it is rarely seen on the slab because of bleeding of concrete. So, it is must to use proper vibration in beams and columns.

Types of Honeycomb in Concrete

There are three types of honeycomb in concrete, such as,

- Small sized honeycomb

- Medium sized honeycomb

- Large sized honeycomb

Small Sized Honeycomb

In this type of honeycomb structure in concrete, the depth of cavities or voids are less than 25mm and as a result the strength of structure is not so compromised.

Medium Sized Honeycomb

In this type of honeycomb in concrete, the depth of cavities or voids are more than 25mm but the reinforcement bars are not exposed. As a result the strength of structure is partially compromised and the bars are vulnerable to water and moisture.

Large Sized Honeycomb

Like the medium sized honeycomb, the depth of cavities or voids are more than 25mm but the reinforcement bars are exposed in this case. As a result the strength of structure is compromised and exposed to water and moisture which promotes corrosion on the bars. This type of honeycomb in concrete is vulnerable during earthquake and other natural hazards.

Causes of Honeycomb in Concrete

The honeycombing in concrete is caused due to the following reasons:

- Honeycomb occurs because of improper ratio of mix design of concrete.

- It also appears when workability of concrete is poorly supervised.

- When casting of any structure is done and the vibration process is not managed properly, the honeycomb severely occurs.

- It also takes place in the structure if the clear cover is not manages properly during placing of formwork.

- It occurs when there is improper grading of aggregates.

- Excess use of water than the water-cement ratio causes honeycomb as it wash away the fine aggregates and cement from the concrete mix.

- Less use of water than the water-cement ratio also causes honeycomb in concrete.

- If wooden formwork is used and the joints of the formwork is not properly closed leaving gaps, then honeycomb occurs due to bleeding of concrete.

- Honeycomb also occurs during casting if the concrete is not poured partly and giving less settling time.

- More amount of large coarse aggregates in a concrete mix which makes hard for the smaller particles to penetrate also causes honeycomb.

- Use of over reinforcement is also one of the cause of honeycomb.

- Pouring of concrete from an excess height i.e., more than allowable height causes honeycomb.

Effect of Honeycomb in Concrete

Honeycomb in concrete causes the following effects:

- Reduction in bearing capacity and strength of structure.

- Air, water and moisture enters into the concrete.

- Corrosion and rusting of reinforcement bars.

- Decreases the life expectancy of the structure.

- Makes a bad aesthetic of the structure.

How to Avoid Honeycomb in Concrete?

Honeycomb in concrete can be avoided by the following points:

- Aggregate grading should be properly done.

- Vibrator should be used with the supervision of an engineer.

- The ratio of mix design concrete should be followed accurately as provided by the engineer.

- Workability of the concrete should be tested.

- Desired clear cover should be provided from the reinforcement bars to the formwork.

- Use of water content should be as mentioned in the water-cement ratio.

- The wooden formworks should be water tight and joints should be rigid.

- Over reinforcement should not be used.

- The pouring of concrete should be from an allowable height.

Honeycomb Concrete Repair

Honeycomb in concrete can be repaired by the following steps:

- Clean the area where honeycomb appears by brushing the loose fine aggregates with a wire brush and clearing the loose coarse aggregates by a chipping hammer.

- Then spray water to the affected area to wash away the dusts present on it.

- Apply chemi-fix glue on the area after the area gets dry. The glue attach properly when the surface is in dry state.

- Mix the concrete grout properly with white cement and add water to it as specified by the manufacturer.

- Lastly, paste the mixture to the honeycomb in the concrete. In large sized honeycomb, make a pocket by the chipping hammer and pour the mixture and then jam the poured mixture with piece of wood or any other formwork material to apply pressure.

- Remove the formwork material after 12 – 16 hours and proper curing of concrete should be done in the area.

You Might Like >

Why Concrete Curing is Important?

Types of Concrete Pump and How it Works

Shotcrete – Benefits, Materials and Application

Concrete Mix Design Calculation

For more information click here.