Stamped Concrete Flooring is an extremely creative substantial development that is widely utilized for floors in pathways, driveways, sidewalks, patios, pool decks, car porches and entrances. Stamped concrete, however ready from traditional cement concrete, is solid and durable and it resembles with natural decorative stones, granites and bricks as a desired pattern and design.

Stamped concrete has many benefits over regular building construction materials and is nearly a maintenance free product. It is a replacement for the natural stones that are used in flooring and as a result it is considered to be a green material in construction.

Here it is discussed about what is stamped concrete flooring, materials needed for stamped concrete flooring, stamped concrete process, stamped concrete specifications, stamped concrete costs, advantages of stamped concrete, disadvantages of stamped concrete and application of stamped concrete.

What is Stamped Concrete Flooring?

Stamped concrete flooring is an extremely keen and creative substantial development that is widely utilized for decorative floors in pathways, driveways, sidewalks, patios, pool decks, car porches and entrances of hotels, offices or other residential buildings. It is very innovative and a low cost construction design for floors.

Utilizing stamped concrete to improve concrete floors gives robustness to the deck as well as gives them a pleasant design. The stamped concrete flooring is also generally known as textured concrete flooring or imprinted concrete flooring.

When it is compared with other regular structural materials like bricks, stones and slates, stamped concrete flooring is more affordable. This product. looks like stone curved plates and the patterned granite floors that are stacked close to one another.

Stamped concrete flooring is also considered as green material for construction, because stamped concrete process saves many natural stones from using as decorative material.

These are the most ideal choices for decorating private structure pool decks, entrances, patios, and courtyards. For the economical construction of outdoor pavements, the stamped concrete has been demonstrated to be the most ideal choice.

Application of Stamped Concrete

The application of stamped concrete are:

- Pathways

- Driveways

- Patios

- Sidewalks

- Pool decks

- Entrances of hotels

- Car porches

- Entrances of offices

- Entrances of residential buildings

- Common area of the commercial stores

Materials Needed for Stamped Concrete Flooring

The materials needed for stamped concrete flooring are:

- Coarse Aggregate

- Fine Aggregate

- Water

- Cement

- Roller

- Woods or Railing for side boundary

- Concrete Mixture Machine

- Vibrating Machine

- Screeding Bar or Planner

- Power Trowel Machine

- Colour Pigments or Colour Powder

- Rubber Pad or Rubber Moulds with Stamped Concrete Patterns

- Stamping Rod

- Wheel Barrow

- Reinforcement or TMT Bars of different diameters

Stamped Concrete Process

The stamped concrete process of flooring includes:

- Preparation of subgrade

- Applying coarse aggregate to the base.

- Running roller over the coarse aggregate base.

- Placing of formworks to the side boundaries.

- Providing reinforcement for strength and stability in case of vehicles.

- Preparation of concrete mixture with proper concrete mix ratio.

- Placing or casting the concrete.

- Screeding of concrete with a screeding bar.

- Finishing and planning of concrete with power trowel machine.

- Applying colour pigments or colour powder over the casted concrete.

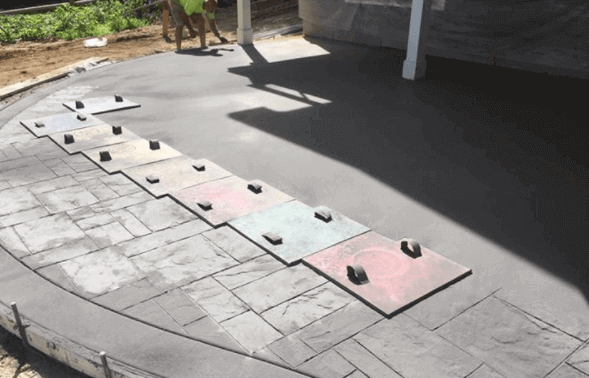

- Stamping the concrete by a stamping rod over the rubber padding or molds with desired stamped concrete flooring patterns and designs.

Stamped Concrete Specifications

Some of the stamped concrete flooring are as follows:

- Stamped concrete flooring is to be executed by an approved specialized agency and an engineer for direction as per the specifications of manufacturer.

- A special grade of concrete is to be used for the base material.

- The colour used for the flooring should be approved colours and UV resistant of regular grade.

- Stamped concrete flooring patterns should be as per the architectural drawings and must approved by an engineer to be made by rubber padding or other imprinting tools.

- It should be cured as per the engineer’s direction.

- The approved acrylic sealer is to be used as per the specifications of the manufacturer and the sealer consumption should not be less than 0.167 L/m2.

- The formworks must be installed as per the architectural drawings and the thickness of the slab should be mentioned in the drawings.

- Expansion joints and construction joints should be provided as specified in the architectural drawings and approved by the engineer.

- Concrete should be screeded by a screeding bar to the finishing grade and the level of the concrete should be made uniform by finishing tools like power trowel machine as per specifications of the manufacturer.

- The released agent should be applied evenly as approved by engineer to the troweled surface.

- At the plastic stage of concrete, the stamped concrete molds or tools are applied to get the desired pattern to the surface.

- After the initial period of curing, the imprinted joints must be grouted and surface should be sealed as per the specifications of the manufacturer.

Stamped Concrete Cost

How much does stamped concrete cost? The stamped concrete cost varies with different stamped concrete contractors and agencies in different region of the world. Generally, the base rate of stamped concrete cost starts from $12.00 to $15.00 per square foot.

If you use more than one pattern or a broader pattern and adding multiple colours with a concrete slab of 6 inch of thickness or more for a driveway or other and if you use concrete pump for high-rise building stamped concrete flooring, then the stamped concrete cost would be more than $15.00 which will be up to $16.00 to $19.00 per square foot.

In this rate of cost the earth works are not included like removing grass and trees, digging and filling of soil. The client should provide the materials, only the installing rate of cost is mentioned above.

How to know the best stamped concrete cost? To know the best stamped concrete cost in your region, visit or contact 3 to 6 agencies or contractors and ask their rate of stamped concrete cost. After that fix your work with an agency or a contractor who is giving low rates with quality work.

To know more about the stamped concrete cost, visit sites for stamped concrete and use their stamped concrete cost calculator.

Advantages of Stamped Concrete

Some of the advantages of stamped concrete flooring are:

- The stamped concrete flooring is very durable.

- The installation or making of the stamped concrete flooring is faster.

- In this product, there are various colour option and various pattern and design options.

- The stamped concrete flooring is maintenance free.

- There is less labour cost in stamped concrete while making.

- The stamped concrete is sealed and free from other weather elements.

Disadvantages of Stamped Concrete

Some of the disadvantages of stamped concrete flooring are:

- The stamped concrete requires periodic resealing and cleaning.

- It requires approved specialized agency and engineer to construct.

- It develops minor cracks due to heat expose.

- However, stamped concrete is maintenance free, but if it requires any repairing, then it is difficult to do so.

So, here it is discussed about what is stamped concrete flooring, materials needed for stamped concrete flooring, stamped concrete process, stamped concrete specifications, stamped concrete cost, advantages of stamped concrete, disadvantages of stamped concrete and application of stamped concrete.

FAQ >

Q. What is the benefit of stamped concrete?

Ans: There are several benefits of stamped concrete but the key benefit is that it is a low cost construction design for floors that saves many natural stones and considered to be a green material.

Q. Can stamped concrete be recolored?

Ans: Yes, stamped concrete can be recolored.

Q. Where can I place a stamped concrete?

Ans: Stamped concrete flooring is widely utilized for floors in pathways, driveways, sidewalks, patios, pool decks, car porches and entrances.

Q. How to seal stamped concrete flooring?

Ans: There are many stamped concrete sealing options in the market, but if you want to seal it chemically then there is limited option. There are generally 2 categories of sealers, such as, penetrating and topical.

You Might Like >

2 Types of Shotcrete and its Benefits

Foam Concrete or Lightweight Concrete

For more information click here.