Prestressed Concrete

Here it is discussed about the types of prestressed concrete, tendons in prestressed concrete and application of prestressed concrete.

Prestressed concrete is fundamentally concrete in which interior stresses of a reasonable magnitude and distribution are presented with the goal that the stresses coming about because of the outside loads are neutralized to an ideal degree. In reinforced concrete individuals, the prestress is for the most part introduced by tensioning the steel support.

The most punctual instances of wooden barrel construction forcibly fitting of metal groups and shrink fitting of metal tires on wood wheels demonstrate that the craft of prestressing has been practiced from ancient times. The tensile strength of plain concrete is just a small portion of its compressive strength and its issue being lacking in tensile strength seems to have been the driving element in the improvement of the composite material known as “reinforced concrete”.

The advancement of early breaks in the reinforced concrete because of incompatibility in the strains of steel and concrete and may be the beginning stage in the improvement of another material like “prestressed concrete”. The use of lasting compressive stress to a material like concrete which is strong or solid in compression yet weak of feeble in tension, builds the apparent tensile strength of that material, in light of the fact that the ensuing utilization of tensile stress should be initially invalidate the compressive prestress.

In 1904, the Freyssinet endeavored to present for all time acting forces in concrete to oppose the elastic forces created under loads and this thought was subsequently evolved under the name of “prestressing”.

Tendons in Prestressed Concrete

An extended component utilized in the concrete individual from construction to grant prestress to the concrete. In general cases, high tensile steel wires, links, cables, strands or bars are used as tendons. It is a medium through which tensile stresses are incited into the concrete. It could be one single steel wire or a gathering of wires turned together to go through the necessary measure of tensile stresses.

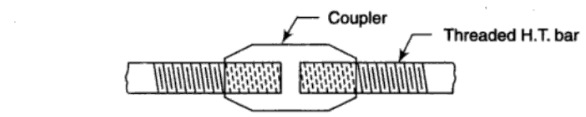

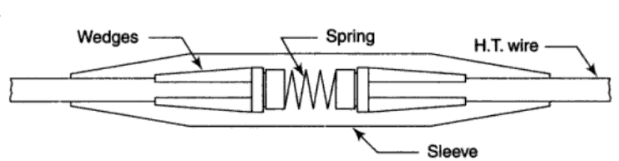

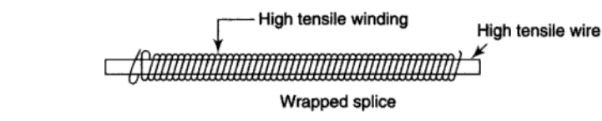

If there should be an occurrence of continuous prestressed concrete members, including long tendons, it is important to splice the tendons to accomplish congruity. A few sorts of splices have been created over the course of the years to suit the various kinds of wires and strands utilized as tendons. A portion of the significant and generally utilized kinds of splicing and game plans are gathered, such as,

- Screw Connector

- Torpedo Splice

- Clamp Splice

- Wrapped Splice

Types of Tendons in Prestressed Concrete

1. Based on tendons in flexible metal sheathing:

- Wire Tendons

- Seven-Wire Strand

- High-Strength Bars

2. Based on tendons in rigid metal duct:

- Seven-Wire Strand

- Mastic Coated Tendons, Seven-Wire Strand and Wire Tendons

- Pregreased Tendons, Seven-Wire Strand and Wire Tendons

Types of Prestressed Concrete

According to the construction method, there are generally three types of prestressed concrete, such as:

- Pre Tensioned Concrete

- Unbonded Post Tensioned Concrete

- Bonded Post Tensioned Concrete

Pre Tensioned Concrete

In this types of prestressed concrete, wires or tendons are tensioned from the beginning and the concretes are poured later. It makes a decent subjugation between the concrete and tendon in such types of prestressed concrete. Subsequently, the tendons are shielded from tensions and corrosion are moved straightforwardly. Tendons are anchored and extended and the stress is moved to the concrete when it is hard. Then, at that point the tendons attempts to return to the first length, however, opposed by the connection between the concrete consequently it prompts compressive force in it.

Unbonded Post Tensioned Concrete

In this types of prestressed concrete, it is minimal not quite the same as fortified post-tensioned concrete. It permits opportunity to move the links or cables. For this, every tendon is covered with oil or grease and covered by plastic in such types of prestressed concrete. The stress moved to the concrete is accomplished by the links or cables through secures or anchors. There are a few advantages or benefits to this, for example,

- The capacity to distress tendons prior to attempting to fix work.

- The capacity to independently change the links or cables.

Likewise, there are a few drawbacks like whenever harmed or damaged, one or beyond what links or cabled can be distress itself and blasted out of the slab.

Bonded Post Tensioned Concrete

In this types of prestressed concrete, like pre-stressing, however here concretes are poured first and then tendons are tensioned. Tendons are put in the appropriate spots in the part and then casting is finished. After the concrete turns out to be hard, the tendons are tensioned by water powered jacks against the concrete. When the tendons have tensioned adequately, as per plan, they are fixed in position. After the jacks are eliminated, tension remaining parts and it moves strain to the concrete. This technique is generally utilized in building slabs for mega house development projects where broad soil some of the times make issues. Additionally, post tensioned concrete is likewise utilized in bridges.

Application of Prestressed Concrete

It is grounded reality that an essential economy of prestressed concrete lies in its high strength to weight and weight to cost proportion, its protection from fire and breaking and its flexibility and versatility. The utilization of prestressed concrete has altered the whole structure industry in the past USSR, USA, UK, Japan and the Continent.

Prestressed concrete structure parts containing empty code and ribbed slabs are broadly utilized in the recent Russia. Single and twofold tee units and channel sections are famous in the USA for the development of floors in structures. Prestressed concrete is unmistakably appropriate for long span bridge construction.

The current pattern is to embrace prestressed concrete for long span cable-stayed bridges which are tastefully prevalent and practical in comparison with steel bridges. As of late, prestressed concrete has discovered novel applications in the development of an assortment of marine designs like, off-shore oil drilling platforms, floating docks, oil storing vessels and large floating liquified gas.

Prestressed concrete has discovered broad application in the development of huge limit fluid holding structures. The utilization of prestressed concrete in tall towers to support restaurants, radio, observation decks and television facilities began in 1953 with the popular Stuttgart tower which is 211 m tall and planned by Prof. Fritz Leonhardt.

The enormous blast in prestressed concrete was proclaimed solely after the Second World War when prestressed concrete was broadly utilized for more than 300 bridges built in Germany during 1949 to 1953. Prestressed concrete was presented in the USA in 1949 for Magnel’s Walnut bridge and around a similar time the Coleroon bridge in South India utilizing the Freyssinet system.

During the most recent 60 years, prestressed concrete has been utilized in the development of building structures and in transportation, environmental, marine, nuclear, oil exploration and power transmission structures. However, the possibility of prestressing emerged out of bridges and as indicated by Raina, bridges have the most impressive engineering design uses of prestressed concrete. The 21st century is good to go to observe testing and creative uses of prestressed concrete in structural engineering works.

Here it is discussed about the types of prestressed concrete, tendons in prestressed concrete and application of prestressed concrete.

For more engineering terms click here.