What is Concrete Pump?

A Concrete Pump truck is a tool that is used for conveying or carrying the freshly mixed liquid concrete from the containers or the batching plants to the construction sites where it needs to be casted or filled. A concrete pump is a very important tool for the big construction projects. The concrete pump is the most used method nowadays for conveying or carrying liquid concrete and became a most common equipment in every construction sites. The concrete pump has expanded the productivity of construction projects, particularly for the tall structures like high-rise buildings.

Here it is discussed about what is concrete pump truck, types of concrete pump, uses of concrete pump, how concrete pump works and advantages and disadvantages of concrete pump.

Over a time of the greater part a century, concrete pumps have gradually taken over from different methods of moving liquid concrete. Various designs of concreting pump were made in the essential portion of the 20th century, but it was Friedrich W. Schwing’s company that is Schwing GmbH who invented in 1957, the twin-cylinder hydraulic concreting pump. The principle of this design was embraced by practically any remaining makers is as yet the overall standard design.

The pump works by one piston bringing the fluid concrete into a cylinder from a hopper or container while the other one simultaneously pushes its concrete out into the release pipes. A valve, which figures out which cylinder is available to the concrete hopper and which one is available to the discharge pipes switches throughout each time the pistons reach the end point and the interaction proceeds with the main cylinder presently releasing and the subsequent drawing new concrete from the hopper.

The Concreting Pump was especially significant in reforming the construction of enormous high-rise buildings. Beforehand cranes had been utilized to lift enormous pails brimming with concrete up to where it was required. A crane could lift each pail in turn, ordinarily holding around 2 cubic yards of concrete. There are many benefits in pumping concrete over this container and crane system. Just as having the option to pump concrete a lot quicker than pails could lift it, it likewise implies a consistent inventory of concrete to the top.

The setting hoses can be situated any place they should be so the liquid concrete can pour straight out of the hose where it is required instead of disseminating a two cubic yard hill of concrete over the ideal area.

Uses of Concrete Pump

Nowadays, it is an exceptionally normal sight to see concrete pumps at any construction site. Be it enormous scale commercial projects or medium-sized construction sites, the state of the art concrete pumping machines are similarly compelling and economical for both. Consequently, in beyond couple of years, concrete pumps have assumed control over any remaining methods of moving liquid concrete at the construction sites. There are different uses for different types of concrete pump truck.

A portion of the uses of concrete pump are:

- This equipment is the most ideal alternative for setting concrete at the construction site at a quicker rate.

- Usage of concrete pumps prompts less requirement of water when contrasted with other concrete pouring methods. Along these lines, when the concrete is put, it will not shrink and crack at all and it will keep up with its strength.

- For complex locations like high-rise buildings or insulated concrete structure dividers, concreting pumps are utilized to increment pouring accuracy.

How Concrete Pump Works

The work of concreting pump are different for the different types of concrete pump truck. Here it is discussed how concrete pump works generally.

- When concrete is required, a mixing truck initially mixes concrete inside its rotating drum.

- Then the truck pours its liquid concrete into a hopper, which keeps on beating the concrete so it won’t harden.

- From that point, the concreting pump empties the liquid concrete from the hopper, through a valve system into the area where it should be casted, with the utilization of auxiliary hoses at times.

- A twin-cylinder hydraulic concrete pump’s interior functions regularly comprise of two parallel cylinders.

- The cylinders have drive pistons inside them that move them to and fro in opposite directions.

- As one cylinder pushes ahead, different moves back. As one cylinder moves back, different pushes ahead.

- The first cylinder, otherwise called the material cylinder, hauls concrete out of the hopper.

- The second chamber or cylinder which is generally known as the releasing cylinder or discharge cylinder, pushes the concrete out of the pump in the spaces and areas where it is required.

- The two pistons work in pair, then again pushing out and pulling in their liquid concrete volumes.

- The hydraulic flow made by the continuous flow of concrete is the thing that causes the two cylinders to substitute to and fro. This continuous flow is additionally imperative to hold the liquid concrete back from setting.

Types of Concrete Pump

There are in general two main types of concrete pump. They are:

- Line Concrete Pump

- Boom Concrete Pump

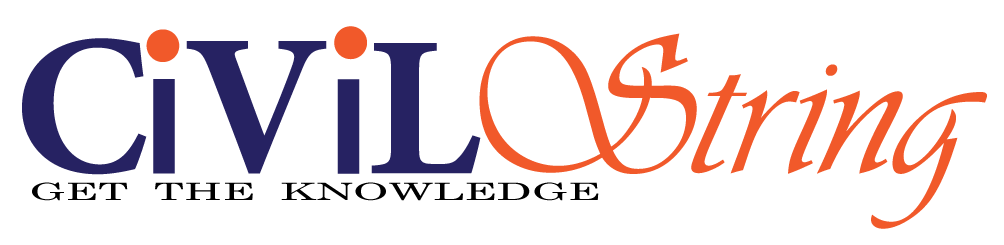

1. Line Concrete Pump

This types of concrete pump truck, pumps the liquid concrete in hoses at about the ground level until the liquid concrete reaches its casting place. In line pump the hoses offer the adaptability to wind through alleys and around houses where the truck will be unable to park. The following are a couple of instances of types of line pumps:

- Stationary Pump: A stationary pump which is also known as a trailer-mounted pump, is a very necessary types of concrete pump. This types of concrete pump truck comprises of a pump mounted onto a little trailer. A separate truck is necessary to tow the stationary pump to the project sites. Since, there is no boom in the stationary pump, so it is necessary to put separate hoses and pipelines to convey the liquid concrete to the area where it is needed to be cast from the pump. A separate putting boom is likewise important to put the concrete exactly.

- Static Truck Mounted Pump: These are the pumps that are placed onto truck beds, so the driver can drive them straightforwardly to the project sites. This types of concrete pump truck don’t have setting booms, however, so they will require the utilization of separate putting hoses to get the concrete where it needs to go.

- Truck Mixer Pump: This types of concrete pump truck is a concrete mixer that mixes the liquid concrete with all the materials. It has also a pump attached that pumps straightforwardly from mixer. This model is effective in various applications, but it requires a project site arrangement that considers driving a tremendous mixing truck straight up near where the liquid concrete ought to be poured.

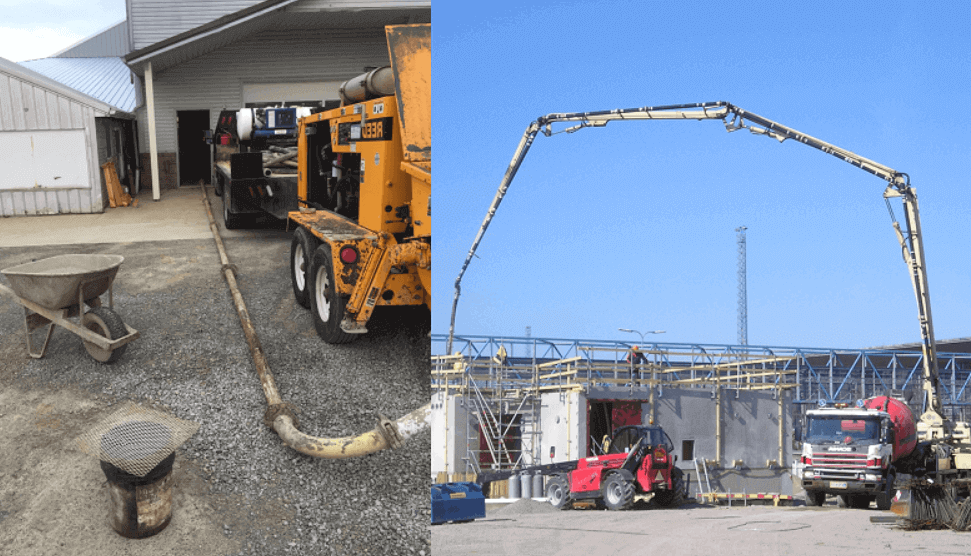

2. Boom Concrete Pump

The boom concrete pump or boom pump is that types of concrete pump truck that stretches out through the air to pump the concrete where it needs to go. It has a long, adaptable, far off controlled arm comprised of explained sections, and the arm reaches out into the air similar as a crane. Boom pump can be utilized for the areas which are hard to reach, and where the line pump can’t reach, like the top floors of a high-rise building or apartment complex.

They can likewise reach over houses and into yards for the construction of lawn swimming pools or garden highlights. At the point when the boom isn’t being used, it folds up into slick fragments on the rear of the truck for transport. Workers can drive this sort of pump straightforwardly to job sites, and the putting boom can put the concrete where it needs to abandon requiring the utilization of additional hoses.

These high-rise concrete boom pump works very rapidly, and these pumps can reach any areas which are reachable for boom. Their user-friendly provisions make this types of concrete pump truck, flexible and famous on construction sites.

The explained sections of boom pump arrive in a couple of different folding configurations:

- Roll and fold: The sections of roll and fold pumps fold one under the following in a curling motion. They are great for vast areas since they need a lot of space to unfold.

- Z and ZZ: The sections of these pumps fold to and fro like an accordion. They are great for fitting through restricted spaces and over and under impediments, for example, over a house and afterward under tree limbs.

- RZ: These pumps, likewise called multifold pumps, have sections are a combination of roll-and-fold and Z sections.

Advantages and Disadvantages of Concrete Pump

Advantages of Concrete Pump

- Much bigger volume of concrete put each hour: A crane would do well lift 12 m³ each hour. A Schwing Static Pump can pump liquid concrete more than 50 m³ per hour to the top of the present tallest building.

- Constant flow: The present models of Schwing Concrete Pump can pump the liquid concrete more speedier than a truck mixer can release into them. Indeed, even as quick as possible discharge much of the time.

- Less man hour wastage: Individuals setting the concrete need to hang tight for the following bunch while the skip is in motion or being topped off at the base. Individuals at the base are simply trusting that the skip will return while it is in motion or releasing at the top. The continuous flow from a concrete pump implies less sticking around.

- The crane can perform different undertakings: Rather than lifting pails of concrete here and there, the crane can be utilized to convey steelwork, scaffolding, formwork and the wide range of various important structure material to where it should be.

- Concrete put directly where you need it: The putting hose can be moved around so that concrete can be set any place it is required. A separate placing boom can likewise be utilized to situate the end hose precisely where it is required inside an enormous area. Mobile concreting pumps accompany their own devoted putting boom.

- Low labor cost: Since the concrete can be put precisely where it is required, just a base number of individuals are needed to appropriate the concrete in contrast to when a skip dumps a load and individuals are expected to then move the concrete to where it is required.

- Setup time of the model is less: Within 60 minutes, the concrete pump show up on the location and extending the booms and outriggers and starts pumping the liquid concrete to a high-rise building many floors up. It can even do two or three such types of project in one day.

Disadvantages of Concrete Pump

- The pumps should be lubricated utilizing a rich mix of mortar prior to utilizing it.

- It is uneconomical for projects with concrete volume lesser than 1000 m³.

- There is a danger of development of blocks in the pumps.

- The conveyance hoses or pipes ought to be spread out in such a manner there are less bends in them and the design of the hose must be continually monitored for any progressions because of the pressure changes inside the pipe.

- The cleaning measure that follows the pumping activity is tedious.

So, here it is discussed about what is concrete pump truck, types of concrete pump, uses of concrete pump, how concrete pump works and advantages and disadvantages of concrete pump.

You Might Like >

Shotcrete Benefits and Materials and Types of Shotcrete

Foam Concrete and its Advantages and Disadvantages

Concrete Mix Design Calculation

For more information click here.